Fil X

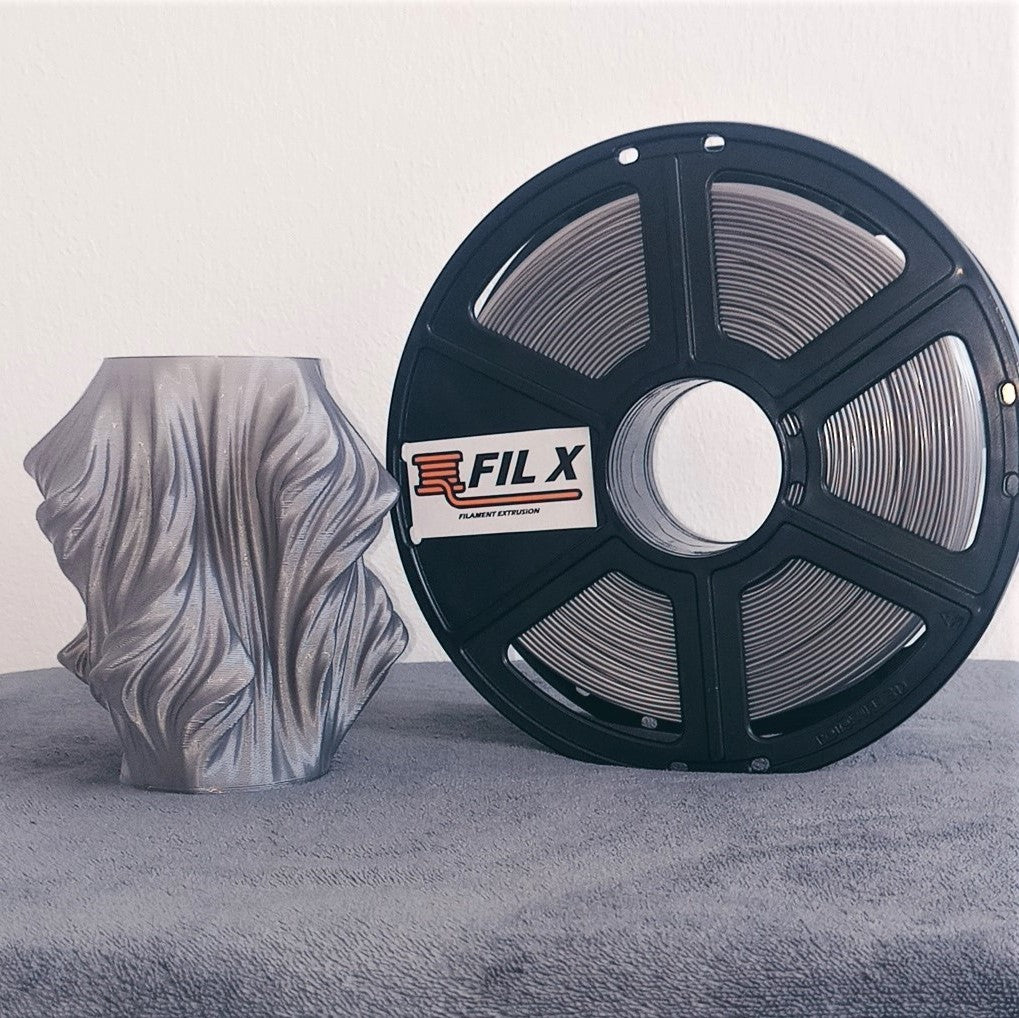

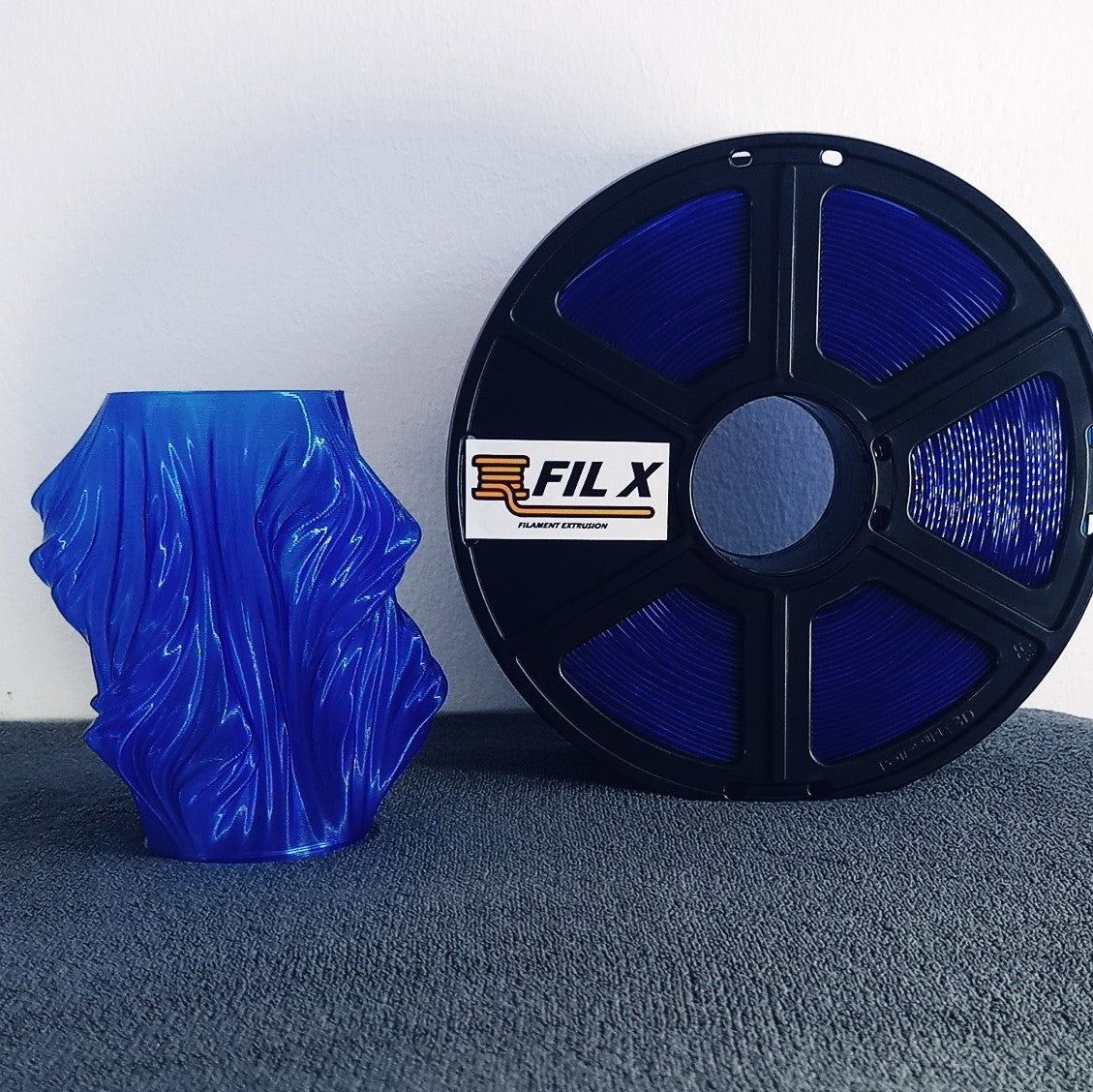

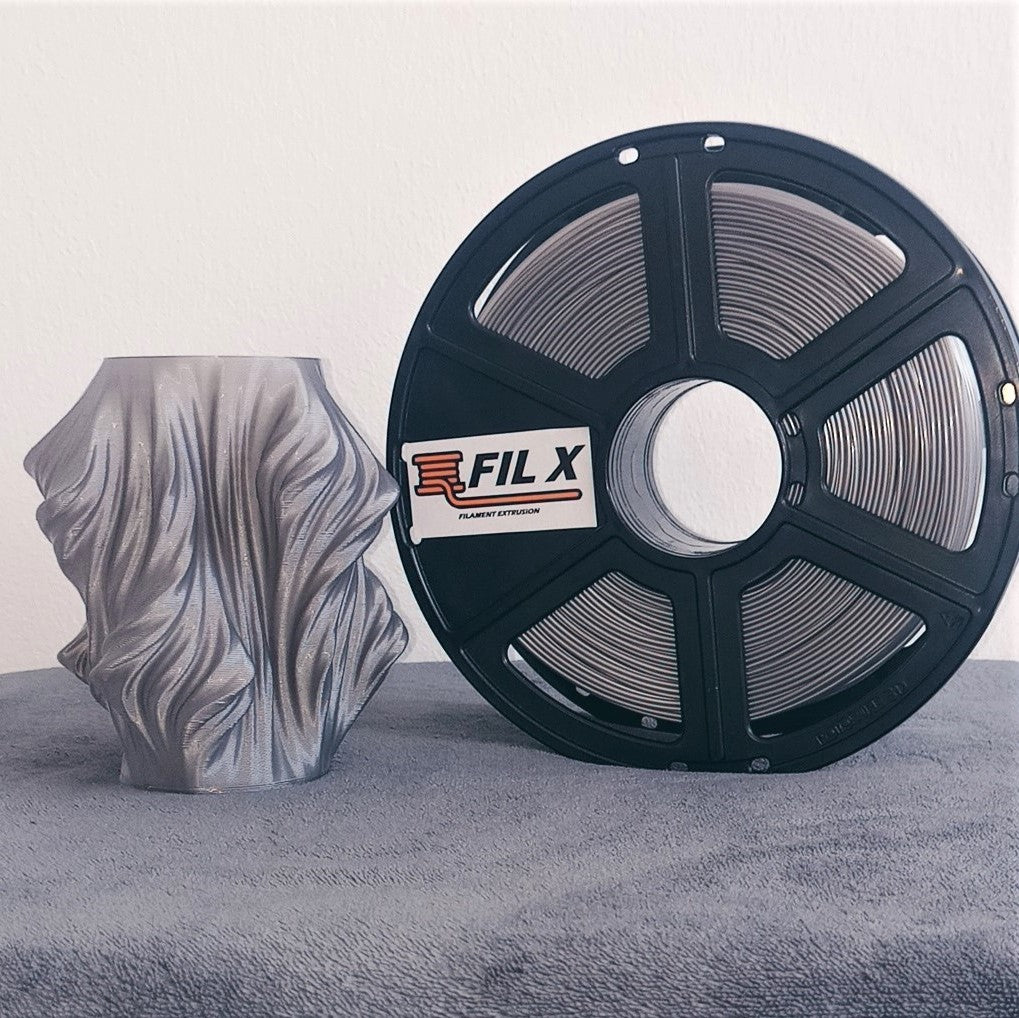

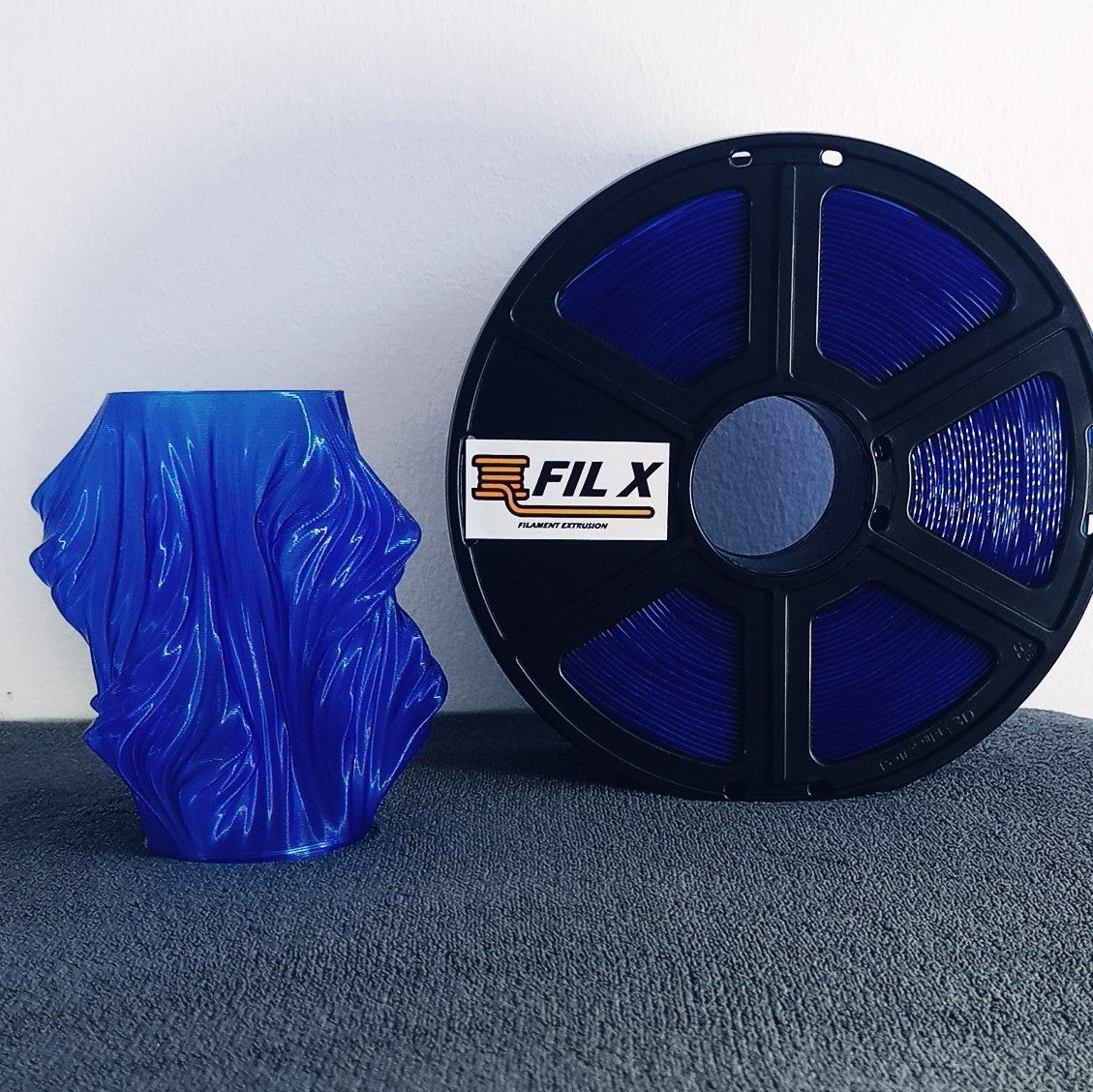

FilX SBS (Styrene butadiene styrene)

Couldn't load pickup availability

Tough yet flexible

SBS can be described as a cross between ABS and TPU: you are in daily contact with SBS products such as the soles of your shoes or the tyres of your car. It has unique properties of being both tough and flexible at the same time, thanks to its Polystyrene origin lending it a hard, tough consistency and the Polybutadiene giving it a bit more bounce with its rubbery properties.

Like ABS, it doesn't take up much moisture; perfect for tropical climates! Like TPU, it is flexible with a high elongation value and resistant to abrasion. Unlike TPU, it doesn't string as much. And unlike ABS, it doesn't give off bad odors (even though we still recommend printing all filaments with exhaust air extractors to minimize long-term risks). Like PLA, it is able to preserve details in your model, with excellent overhang performance. Supports are even easier to remove than PLA.

That's not all. It is safe for food-contact applications, and because it is less dense than PLA (about 33% less), you get better value: expect about 430m from a single 1kg spool versus 330m from an equivalent mass of PLA.

Reasons to use SBS

- Unaffected by moisture

- Value for money: about 430m for 1kg! For comparison, PLA is typically about 330m for equivalent mass.

- Can be smoothed with citrus oil

- Little to no odor unlike ABS

- Food-contact safe

- Excellent for reproducing detail

- Excellent overhang performance

- Easy to remove when used as support interface, leaving no blemishes

Specifications

| Diameter | 1.75mm |

| Weight | 1kg nett |

| Nozzle temperature | 210–230˚C |

| Bed temperature | 70˚C |

| Bed adhesion | PVA glue suggested |