Prusa Research

Original Prusa MMU3 upgrade kit (for MK3.9/S/MK4/S)

Couldn't load pickup availability

Print up to five (5) filaments at the same time with high speed and low waste. As an add-on for the Original Prusa i3 MK3.9 and MK4, it enables automatic switching between loaded materials. MMU3 is fully supported in PrusaSlicer by an easy multi-material painting tool, and it offers efficient and filament-saving color printing to everybody.

What's new in MMU3?

- Use any 1.75mm spool, no need to re-spool! Cardboard, extra wide, extra-slim 250g spools, 8kg, 12kg, whatever you like

- Freedom to use active or passive dryer(s) to keep hygroscopic filaments in optimal state

- Brittle/broken filament can be easily removed without the use of tools

- Fast filament swaps. Only Prusa XL is faster

- No flying “poop” (purge waste) that lands on and ruins your print. No backed-up “poop chute” that causes your print to fail.

- Completely new firmware written from scratch

- Full two-way communication with the printer, Compatible with the MK3.9 and MK4

- LCD screen integration (status messages, real-time information, error codes)

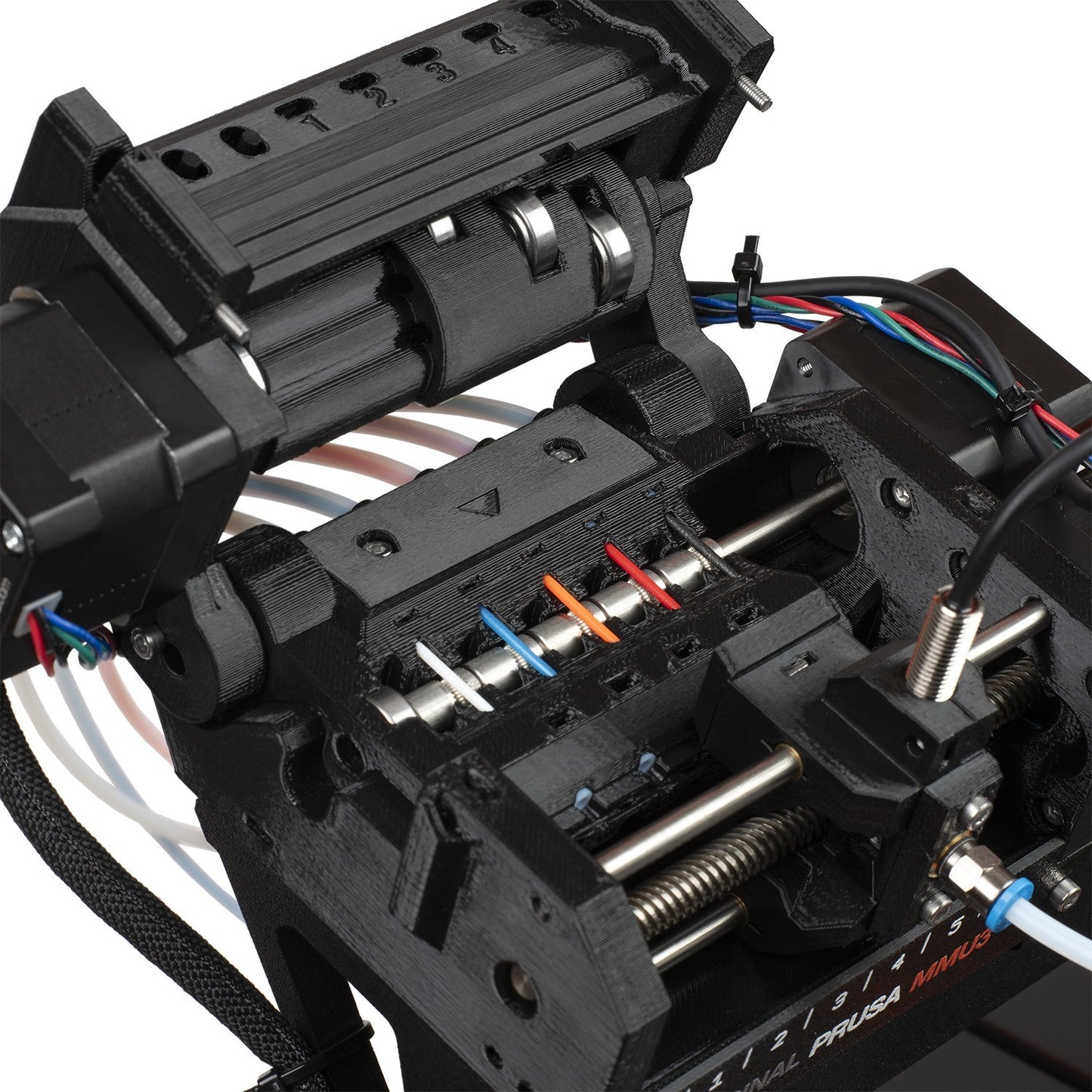

- All plastic parts were redesigned with a focus on easier assembly and maintenance

- New metal parts to make the unit more robust and reliable

- Improved electronics

Efficient multi-color printing

Every time you switch filaments, you need to purge the previous material from the nozzle to prevent cross-contamination. There are various ways to do it and the MMU3 uses an efficient “wipe tower” - it’s a compact, partially hollow block next to the printed object where the filament is purged and the pressure in the nozzle is stabilized. All filament goes into one location and you don’t need to worry about bits of plastic piling around your printer.

We’re offering multiple ways how to save filament and reduce plastic waste - PrusaSlicer gives you options for “wipe into infill” (the printed object’s infill is used as a wipe tower) or you can use “wipe into object” where another object is used as a wipe tower - it will be very colorful but if you, e.g., need a functional part or you will paint it later, it’s a great way to reduce plastic waste to a minimum.

Package includes

- MMU electronics

- MMU motor set

- Printed parts or filament (2x 400g), depending on variant

- SuperFINDA

- PTFE tubes and others

- Fasteners

- Spoolholders (5x)

- Buffer plates (6x)

Variants

All variants DO NOT INCLUDE MK4 printer!

Kit: you assemble everything. Will take at least 4 hours. Does not include printed parts necessary for assembly, so you have to print your own!

Kit + printed parts: you assemble everything. Nextruder parts such as the MJF main plate are in the kit, supplied by Prusa. All current versions of the parts needed are provided in Prusament PETG black or orange, unless it's a custom order. Two working days lead time needed.

Reified: ready to go, assembled here in Singapore! All you need to do is to hook it up to MK4's Buddy board, position the buffer and spools, and perform filament calibration. Should take 30 minutes. Three working days lead time needed.