Fillamentum INDUSTRIAL

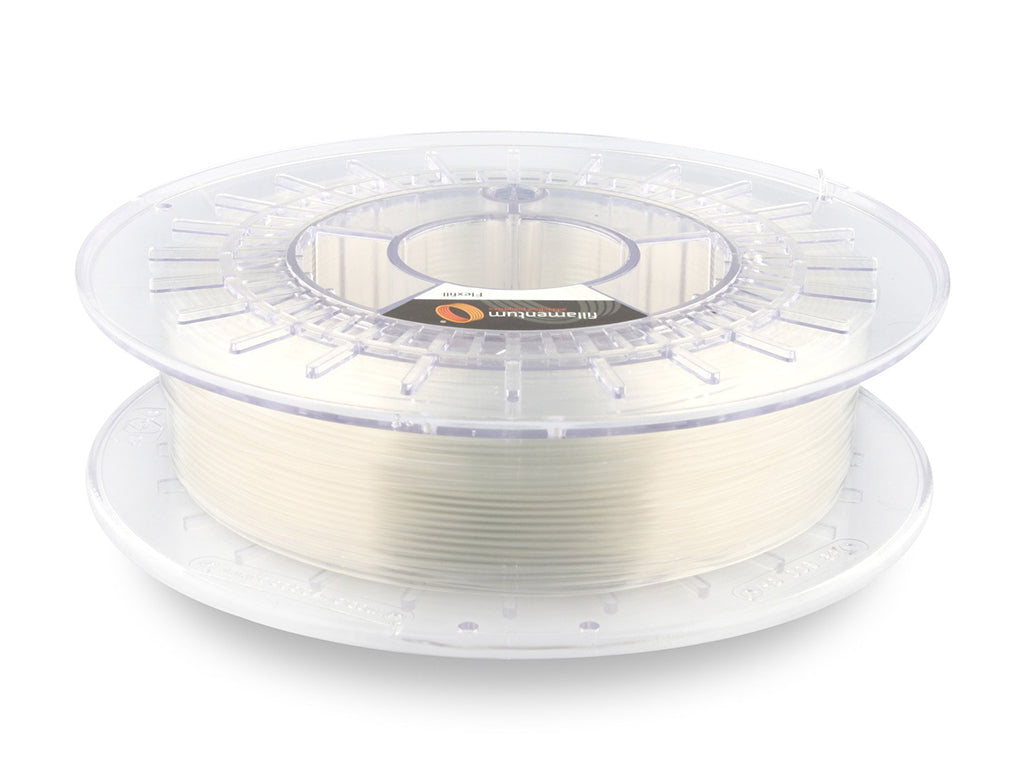

Flexfill TPU 92A 1.75mm 500g Natural

Couldn't load pickup availability

Thermoplastic polyurethane with hardness 92 Shore A. A technical flexible filament that offers great mechanical properties such as high tear and tensile strength.

It is characterized by highly reversible deformation, resistance to ozone, oils, greases, and aliphatic alcohols. Wear resistance guarantees the durability of 3D printed products. Great for the printing of continually sliding parts or sealings.

Features:

- Can be used for the final surface treatment

- Great interlayer adhesion ensuring tear strength in all the directions

- Excellent abrasion resistance

- Good rebound resilience

- High elasticity with highly reversible deformation

- Safe to use in electrical and electronic equipment

- Flexible

- Low warping

- BPA-free and styrene-free

- Recyclable

| Working temperature: | 220–240 °C |

| Heated bed: | 50–60 °C |

| Diameter: | 1.75 mm and 2.85 mm |

| Diameter tolerance: | +/- 0.10 mm |

| Weight: |

500 g of filament (+ 230 g spool)

|

| The length of the filament: |

175 m (1.75 mm, 500 g)

70 m (2.85 mm, 500 g)

|

| RAL | Pantone | HEX: |

N/A | N/A | N/A

|

Comparison of our Flexfill family:

| Flexfill TPU | Flexfill TPE | Flexfill PEBA | ||

| Polymer base | Polyurethane + ester | Polyolefin + SEBS | Polyamide + ether | |

| Tensile strength | 49 MPa | 5 MPa | 36 MPa | |

| Elongation at break | 600 % | 250 % | > 1000 % | |

| Density | 1.20 g/cm3 | 1.15 g/cm3 | 1.00 g/cm3 | |

| Sensitivity to moisture | High | Low | High | |

| Chemical resistance | Oils, greases, ozone | Water, acids, alcohols, alkalis | Car fluids, toluene, acetone, ozone | |

| Food & skin contact | Not recommended | Certificated | Not certificated | |

| Gas permeability | High | Low | Medium | |

| Optical properties | Glossy, transparent | Matte, non-translucent | Glossy, very transparent | |

| For example, ideal for applications | Vibration | Anti-vibration, damping | Anti-vibration, damping | Vibration and energy transfer |

| Skin contact | - | Long-term touch of human skin (holding in hands) | - | |

| Under temperature | +80–100 °C | +80 °C | -40 °C | |

| In contact with | Oils | Water | Car fluids | |

| Abrasion | Sliding abrasion | - |

Impingement abrasion |

|

| Other | - | Outdoor | Low density | |

| - | - | Rebounding |

The input material was carefully selected to achieve the best processability and final properties. Fillamentum’s products are always produced from the precisely specified type of material, with the highest stability across all the batches. The customers can rely on the best quality at any time they use our filament.